Engineering That Matters

Deep Foundation “Feedback”: Valuable Early Data From The Jobsite

9/15/2021

The Reality

A recognized challenge for geotechnical engineers designing deep foundations is utilizing information on subsurface soils from a finite number of subsurface explorations (e.g., test borings with Standard Penetration Test sampling). If the geotechnical engineering consultant that was hired to coordinate and report on the explorations performs their work within the standard of care, the number of explorations performed at the site is appropriate and useful for characterization of a site’s soil profile. From a well-coordinated subsurface exploration program, a geotechnical engineer is able to develop a representative understanding of the composition and strength of subsurface soils (including rock and obstructions where present) at a site. It’s no mystery that SPT boring logs are routinely used in the design of deep foundations, especially considering the many empirical correlations between SPT blow count and engineering properties of soils that have been established since the test method was standardized in the mid-1950s.

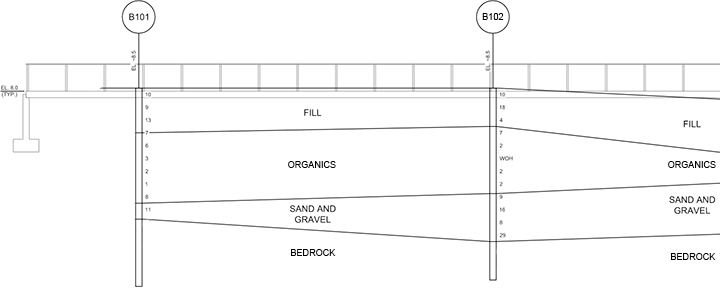

While SPT boring logs and an accompanying professional geotechnical report are very useful in developing an understanding of the soil (and groundwater) conditions at a project site, they are understandably limited to sampling and classification at their respective locations only. Geotechnical engineers are regularly considering the possibility for variations to exist at locations where explorations were not performed. As an example, if a test boring encounters rock at a depth of 30 feet below existing grade at its location – and another test boring 50 feet away encounters rock at a depth of 40 feet below existing grade at its location – then it is reasonable practice to assume that rock is at a depth of approximately 35 feet below existing grade at the midpoint between the two test borings. Interpolations of the depths to various soil strata are commonly performed, using the data logged at the test boring locations as “limits” to what can be reasonably expected at intermediate locations.

However, the geotechnical engineer that develops a helical pile design is not limited to evaluating the adequacy of the design only before construction takes place. For several decades, helical pile manufacturers have considered established correlations between a helical pile’s installation torque and its ultimate (“as-installed”) capacity – based on the analysis of data from hundreds of static load tests performed on helical piles. Analysis of such load test data enables the reviewing engineer to determine if the tested pile has an ultimate capacity greater than that required. This data can also be used to determine the allowable design load, considering deflections that exceed established limits during testing.*

Helical pile designers present the installation torque that is required for achievement of the ultimate pile capacity. In addition to presenting the required installation torque, a helical pile designer will present the anticipated depth at which the pile is expected to develop its required bearing capacity. Conflict often arises when a minimum pile depth (or tip elevation) is specified in addition to a required installation torque. The reason is natural variations may exist, or there may be varying levels of conservatism in the soil properties correlated to SPT blow count and considered in the design by the engineer, that lead to the pile achieving its required installation torque at depths different than the design depth estimated/established by the helical pile designer. Minimum depth requirements make sense only when there is a depth-dependent design concern – such as layers of compressible or liquefiable soils, or a scour depth that the helical pile needs to bear below. When there is not a depth-dependent design concern, the helical pile designer need only present the required installation torque [for correlation to capacity] and the anticipated depth at which the pile will develop its required ultimate capacity.

For example, a helical pile designer may state an anticipated depth (or elevation) at which the pile should develop its ultimate capacity. If the data from such a program (i.e., test borings) suggest the pile will have the required bearing capacity at 25 feet below existing grade, it should not be a serious design concern if the pile achieves its correlated installation torque at a depth of 22 feet or 28 feet instead. The installation torque observed and recorded during helical pile installation should be used as a means of generally validating the results of the subsurface exploration program. Ideally, the helical pile designer could be made aware of the depths/elevations at which the piles achieved their installation torque – namely for the first helical piles installed on the project. This gives the design engineer and the installer an early opportunity to discuss whether those depths/elevations are reasonable and satisfy the design engineer’s expectations, prior to the installation of the remaining piles.

A recognized challenge for geotechnical engineers designing deep foundations is utilizing information on subsurface soils from a finite number of subsurface explorations (e.g., test borings with Standard Penetration Test sampling). If the geotechnical engineering consultant that was hired to coordinate and report on the explorations performs their work within the standard of care, the number of explorations performed at the site is appropriate and useful for characterization of a site’s soil profile. From a well-coordinated subsurface exploration program, a geotechnical engineer is able to develop a representative understanding of the composition and strength of subsurface soils (including rock and obstructions where present) at a site. It’s no mystery that SPT boring logs are routinely used in the design of deep foundations, especially considering the many empirical correlations between SPT blow count and engineering properties of soils that have been established since the test method was standardized in the mid-1950s.

While SPT boring logs and an accompanying professional geotechnical report are very useful in developing an understanding of the soil (and groundwater) conditions at a project site, they are understandably limited to sampling and classification at their respective locations only. Geotechnical engineers are regularly considering the possibility for variations to exist at locations where explorations were not performed. As an example, if a test boring encounters rock at a depth of 30 feet below existing grade at its location – and another test boring 50 feet away encounters rock at a depth of 40 feet below existing grade at its location – then it is reasonable practice to assume that rock is at a depth of approximately 35 feet below existing grade at the midpoint between the two test borings. Interpolations of the depths to various soil strata are commonly performed, using the data logged at the test boring locations as “limits” to what can be reasonably expected at intermediate locations.

However, the geotechnical engineer that develops a helical pile design is not limited to evaluating the adequacy of the design only before construction takes place. For several decades, helical pile manufacturers have considered established correlations between a helical pile’s installation torque and its ultimate (“as-installed”) capacity – based on the analysis of data from hundreds of static load tests performed on helical piles. Analysis of such load test data enables the reviewing engineer to determine if the tested pile has an ultimate capacity greater than that required. This data can also be used to determine the allowable design load, considering deflections that exceed established limits during testing.*

Helical pile designers present the installation torque that is required for achievement of the ultimate pile capacity. In addition to presenting the required installation torque, a helical pile designer will present the anticipated depth at which the pile is expected to develop its required bearing capacity. Conflict often arises when a minimum pile depth (or tip elevation) is specified in addition to a required installation torque. The reason is natural variations may exist, or there may be varying levels of conservatism in the soil properties correlated to SPT blow count and considered in the design by the engineer, that lead to the pile achieving its required installation torque at depths different than the design depth estimated/established by the helical pile designer. Minimum depth requirements make sense only when there is a depth-dependent design concern – such as layers of compressible or liquefiable soils, or a scour depth that the helical pile needs to bear below. When there is not a depth-dependent design concern, the helical pile designer need only present the required installation torque [for correlation to capacity] and the anticipated depth at which the pile will develop its required ultimate capacity.

For example, a helical pile designer may state an anticipated depth (or elevation) at which the pile should develop its ultimate capacity. If the data from such a program (i.e., test borings) suggest the pile will have the required bearing capacity at 25 feet below existing grade, it should not be a serious design concern if the pile achieves its correlated installation torque at a depth of 22 feet or 28 feet instead. The installation torque observed and recorded during helical pile installation should be used as a means of generally validating the results of the subsurface exploration program. Ideally, the helical pile designer could be made aware of the depths/elevations at which the piles achieved their installation torque – namely for the first helical piles installed on the project. This gives the design engineer and the installer an early opportunity to discuss whether those depths/elevations are reasonable and satisfy the design engineer’s expectations, prior to the installation of the remaining piles.

The Opportunity

While there are no strict guidelines on what is an acceptable difference between the design engineer’s anticipated design depth and the depth at which the pile truly achieves its installation torque, it is reasonable to say that there are some limits to what is considered to passably meet with the designer’s expectations during the design phase. If several boring logs suggest the pile’s design bearing elevation is anticipated to be approximately 35 feet below existing grade in a dense to very dense sand, additional evaluation may be warranted if most piles at intermediate locations achieve their installation torque at a depth of approximately 20 feet. While the pile may very well perform just fine at that shallower depth, it is apparent the geotechnical engineer had a different understanding of subsurface soil conditions as depicted by the boring logs. This is not a reflection of a poor subsurface exploration program or poor reporting, either. It just may be that a dense/stiff, suitable bearing layer was not encountered at the test boring locations at this shallower depth. However, with potentially several boring logs – and each not encountering such – additional exploration may be warranted to explore the reason for achieving installation torque significantly shallower than what had been expected (e.g., unanticipated obstructions), and/or static compression load testing can be performed to evaluate the pile’s performance at this shallower depth.

Designing helical piles – or any deep foundation type – is interesting and engaging, as it almost certainly involves generalizing the properties of subsurface soils that are not visible from the existing ground surface. However, helical pile designers and installers should consider the important “feedback” on soil conditions that exist during helical pile installation, in the form of the installation torque observed during their installation.

Not everything that can be learned about the soils at a project site come from test borings or test pits, prior to construction. When designing in soils I’ve never seen, touched or explored everywhere across the site, I’m happy to hear anything that tells me a little bit more about the soils there than I knew before – even if that comes during pile installation.

While there are no strict guidelines on what is an acceptable difference between the design engineer’s anticipated design depth and the depth at which the pile truly achieves its installation torque, it is reasonable to say that there are some limits to what is considered to passably meet with the designer’s expectations during the design phase. If several boring logs suggest the pile’s design bearing elevation is anticipated to be approximately 35 feet below existing grade in a dense to very dense sand, additional evaluation may be warranted if most piles at intermediate locations achieve their installation torque at a depth of approximately 20 feet. While the pile may very well perform just fine at that shallower depth, it is apparent the geotechnical engineer had a different understanding of subsurface soil conditions as depicted by the boring logs. This is not a reflection of a poor subsurface exploration program or poor reporting, either. It just may be that a dense/stiff, suitable bearing layer was not encountered at the test boring locations at this shallower depth. However, with potentially several boring logs – and each not encountering such – additional exploration may be warranted to explore the reason for achieving installation torque significantly shallower than what had been expected (e.g., unanticipated obstructions), and/or static compression load testing can be performed to evaluate the pile’s performance at this shallower depth.

Designing helical piles – or any deep foundation type – is interesting and engaging, as it almost certainly involves generalizing the properties of subsurface soils that are not visible from the existing ground surface. However, helical pile designers and installers should consider the important “feedback” on soil conditions that exist during helical pile installation, in the form of the installation torque observed during their installation.

Not everything that can be learned about the soils at a project site come from test borings or test pits, prior to construction. When designing in soils I’ve never seen, touched or explored everywhere across the site, I’m happy to hear anything that tells me a little bit more about the soils there than I knew before – even if that comes during pile installation.

* Note: 1.ICC-ES AC358 Acceptance Criteria for Helical Foundation Systems and Devices considers a helical pile’s maximum load capacity to be that at which the pile deflection exceeds 10 percent of the average helix plate diameter.

Never Settle

Make a solid decision CONTACT US NOW

|

Earth Anchoring Suppliers, LLC

Headquarters: 19 Trenton-Lakewood Road Clarksburg, New Jersey 08510 Mailing: 424 Stagecoach Road - No. 73 Clarksburg, NJ 08510 P: 732.747.7222 F: 609-223-0125 E: [email protected] Privacy Policy |

CHANCE® Civil Construction is a division of Hubbell Power Systems, Inc., the international leader in earth anchoring. CHANCE and ATLAS® brands are used worldwide in a variety of deep foundation applications.

|

© Earth Anchoring Suppliers. All rights reserved.

This website uses marketing and tracking technologies. Opting out of this will opt you out of all cookies, except for those needed to run the website. Note that some products may not work as well without tracking cookies.

Opt Out of Cookies©

Web Design by Harbour Light Strategic Marketing